|

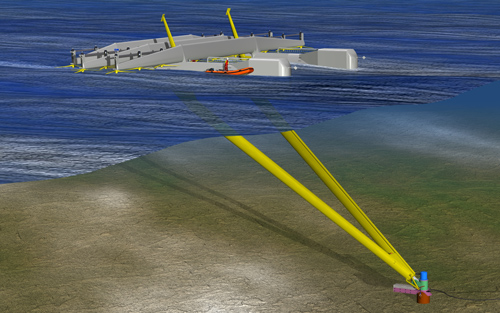

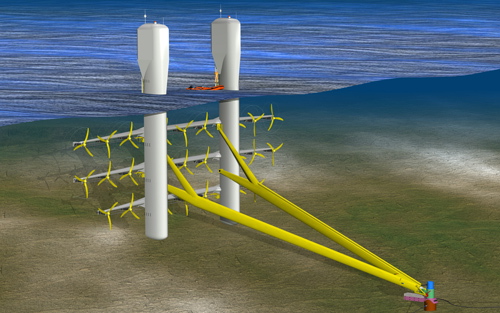

Rotor blade for innovative tidal generator

At flw speeds of up to 5 m/s, the rotors of tidal generator

are subjected to high dynamic loads. In response, an

intelligent, heavy-duty CFC rotor blade has been developed and

produced by Avantgarde Technologie GmbH for the SCHOTTEL Group

using VAP® technology and process engineering

support from Composyst GmbH.

To limit the shearing forces that can occur at overspeed, the

intelligent blade adjusts in shape to enlarge its pitch angle.

This significantly reduces thrust augmentation and keeps the

load exerted on the tur bine and the supporting structure at a

low level. The high load capacity and thus operational safety

of the weight-reduced rotor blades is achieved in an integral

production concept realized in the VAP® process for

highly reliable infusion results.

In fact, VAP® delivers mechanical design

implementation in aviation quality. The CFC preforms are

dry-stacked and can be optimally draped even in the extreme

geometry areas of the blade. By using a VAP®

membrane system by Trans-Textil GmbH, Avantgarde Technologie

also achieves homogeneous fiber volume content in the blade.

Accordingly the blade offers reliable structural properties

from its innovative load transfer hub to its tip.

|