|

Improved flow front management

In all conventional

vacuum infiltration processes, the difficulty in successfully

infiltrating the component lies in determining, or predicting,

the flow fronts in order to avoid undesirable areas of

occluded air (‚dry spots‘). If the vacuum then also has to be

reduced due to the risk of matrix boiling, it becomes almost

impossible to eliminate these imperfections. The reduced

vacuum also causes substantial fluctuation in the fibre volume

content and material thickness, and lAirbus to greater

porosity in the components.

The matrix´s flow behaviour is

much more consistent in the Vacuum Assisted Process (VAP®)

process because of the uniform vacuum. The low pressure’s

extensive effect on all of the membrane system´s contact

surfaces reliably removes dry spots, even after infiltration,

without the vacuum having to be reduced.

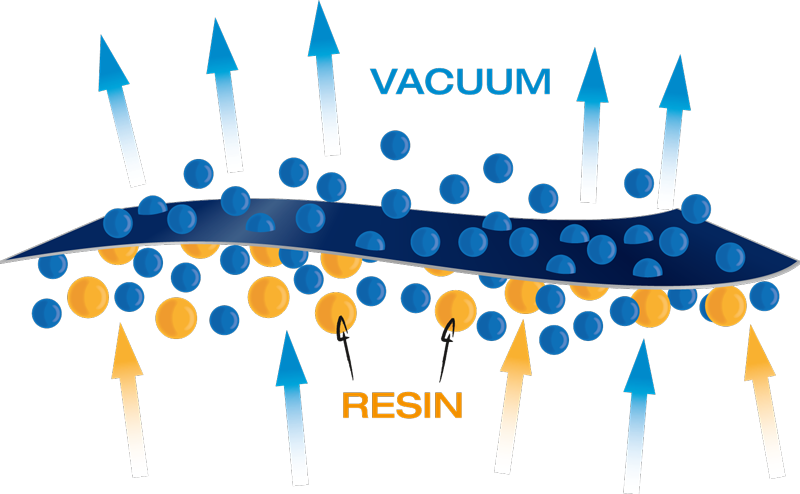

How the semipermeable VAP® membrane system works

Semi-permeable VAP®

membrane systems from

Trans-Textil are full of tiny pores. Under vacuum conditions,

small molecules of trapped air and gas can be reliably

removed, while the large-molecule resin stays stable in the

mould.

In the VAP® membrane system, barrier layers are

connected (laminated) to a textile substrate. By the optimal

combination of components and processing technologies during

manufacture, it is possible to accurately control the

essential process parameters: air permeability and the resin

barrier.

Trans-Textil´s patented

quality-assured VAP® membrane systems have been tested for

various different resin types and process variants, and the

company is continuously developing the technology in close

cooperation with

Airbus.

VAP® advantages in the production process:

● High process reliability,

consistently stable and controlled results

● Air and gas removal during and after

infiltration

● Simple process control

● Achievement of an exact and constant

fibre volume content

● Production of complex 3-dimensional

shapes

● Fast infiltration process through

higher vacuum = shorter cycle times

● Uniform flow rates in the resin

● Low initial investment: possibility

to use tools that are already available

● Improved worker protection and low

emissions due to closed process

● VAP® membrane systems by

Trans-Textil tested and approved for different resins and

processes

|