|

VAP®3D: Solutions adapted to component

form

As

part of the AZIMUT and RoCk projects and working in response

to calls for automated and optimized process chains,

Trans-Textil and its partners have developed a new

made-to-shape approach especially devised for large aviation

structures that need to be fabricated in one integral process.

Starting with the geometry data of the Airbus A350 pressure

bulkhead, this involved compiling the layers in the VAP®

process lay-up into a VAP® 3D material kit made up of

instant-use textile auxiliaries that have been tailored to the

precise shape of the component mold. Aviation-qualified

materials combined in newly-developed cutting and joining

techniques were solely used.

The

large-scale, multi-layer made-to-shape solutions come with

robot grip straps for swift, automatic and

precisely-positioned layer stacking in the mold. This almost

entirely eliminates the need for laborious cutting work and

other preparatory tasks such as joining, positioning,

repositioning and fixing the layers by hand. The VAP®

3D material kit has already proved its worth in a trial

involving a full-size Airbus A350 pressure bulkhead.

Practice-oriented adaptation

Thanks to the applications engineering

experience of the VAP® Network partners and their expertise in

made-to-shape solutions, VAP® membrane systems proven in

aviation and industrial applications and further textile

components (such as 01870 Flow Aid by Trans-Textil) can now be

adapted to specific individual requirements for component

fabrication.

Quality made in Germany

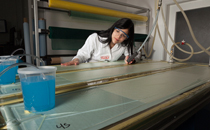

In

its VAP® lab, Trans-Textil develops and tests combinations of

membrane laminates, resins and processing approaches under

realistic conditions. In

its VAP® lab, Trans-Textil develops and tests combinations of

membrane laminates, resins and processing approaches under

realistic conditions.

Oeko-Tex certificate confirms human ecology

safety

With the

certification of VAP® products “Made in Germany” to the latest

criteria of the Standard 100 by Oeko-Tex, Trans-Textil and

Composyst once again demonstrate the high environmental

standard of their vacuum infusion products. In the manufacture

of our patented semi-permeable functional product CS/E, 3D ready-mades,

multi-layer systems and flow media we intentionally avoid the

use of polluting substances. Free of substances classified as

hazardous, the products ensure a high level of process

performance in the VAP® technology combined with occupational

safety as well as the lowest emissions during production and

use.

The Standard 100 by

Oeko-Tex is an international, independent testing and

certification system for textile products. It certifies the

human ecology safety as well as the conformity with all

currently valid limit values in part far beyond the legal

requirements.

Airbus and Trans-Textil are owners of patents on membrane products and processes in the field of vacuum infusion, e.g. VAP® vacuum Airbus and Trans-Textil are owners of patents on membrane products and processes in the field of vacuum infusion, e.g. VAP® vacuum

infusion process (DE 102010 011 067 B4 and DE 10 2008 006261 B3 as well as international PCT patent application WO 2011/110340 A1

and WO 2009/092543 A1, as well as domestic and foreign patent applications and patents resulting therefrom). Without the consent of Airbus

and Trans-Textil, the patented membrane products may not be manufactured, offered, supplied, placed on the market, used or imported for the aforementioned purposes, nor may they be owned. The use of such membrane products for resin infusion processes is only permitted in

connection with membrane products manufactured by Trans-Textil GmbH. The membrane products are purchased from the authorized distributor Composyst GmbH. VAP® and the VAP logo are internationally registered trademarks of Airbus Defence and Space GmbH. Their use is only

permitted with the consent of the trademark owner.

» Request information

|